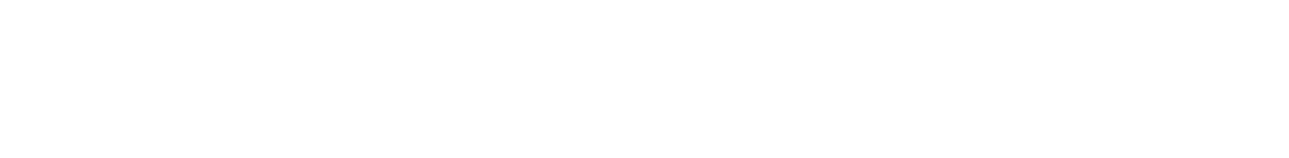

THE RTD

ULTRA ROBUST FOR MORE POWER

Built on a larger and more robust structure (+20,000lbs), the RTD is a real workhorse. With its 25HP HSD Spindle and an optional automatic loading and unloading system, it can do everything.

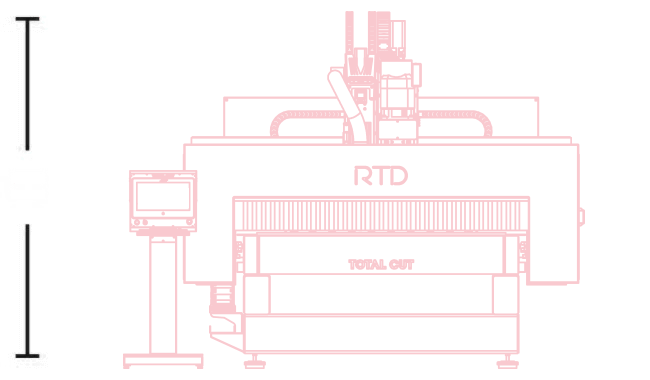

TABLE SIZE CHART

| Model | Length | Width | Height | Cutting Area |

| RTD 510 | 211" | 108" | 109" | 60" x 120" |

| RTD 612 | 235" | 120" | 109" | 72" x 144" |

| RTD 824 | 470" | 144" | 109" | 96" x 288" |

| RTD 1060 | 1,175" | 168" | 109" | 120" x 720" |

OTHER CNC ROUTER MODELS

THE RTC

The ideal high performance scalable solution for small to medium manufacturing needs.

THE RTS

A router built to handle the toughest cutting applications with precision and accuracy.

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

English

English  Français

Français