THE RTS

PRECISION AND ACCURACY

The RTS router is perfect for customers looking to cut many types of materials with affordable performance. With its heavy-duty frame and its 1″ thick solid aluminum 4-zoned vacuum table, this machine is built for continuous industrial use.

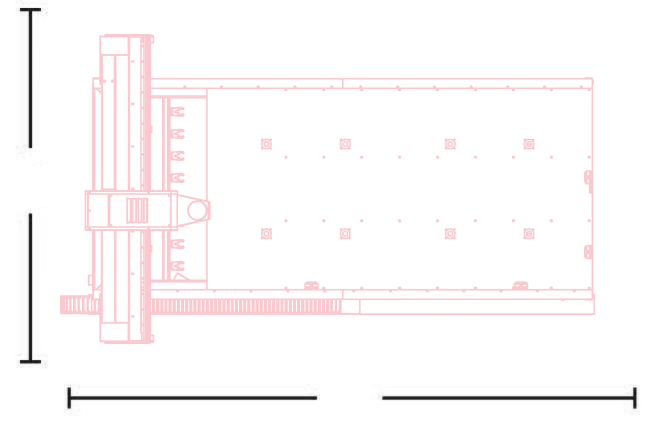

TABLE SIZE CHART

| Model | Length | Width | Height | Cutting Area |

| RTS 48 | 135" | 86" | 78" | 48" x 96" |

| RTS 510 | 159" | 98" | 78" | 60" x 120" |

| RTS 612 | 173" | 110" | 78" | 72" x 144" |

| RTS 824 | 346" | 134" | 78" | 96" x 288" |

OTHER CNC ROUTER MODELS

THE RTC

The ideal high performance scalable solution for small to medium manufacturing needs.

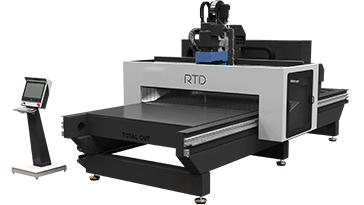

THE RTD

Bigger and stronger, the RTD is a real workhorse. With its 25HP HSD spindle, it can do everything.

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

English

English  Français

Français