THE TC2

MODULAR BRIDGE AND RAIL CUTTING SYSTEM

The TC2 is a medium to heavy duty modular design, built for maximum flexibility. This table can also accommodate the requirements of a production environment with a limited budget as the customer can build the table section by himself.

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

OTHER CNC PLASMA TABLE MODELS

THE TC3

The TC3™ Plasma Table is a plate processing machine engineered for the most demanding customers such as Steel Service Centers, Ship Building and Structural Steel Applications.

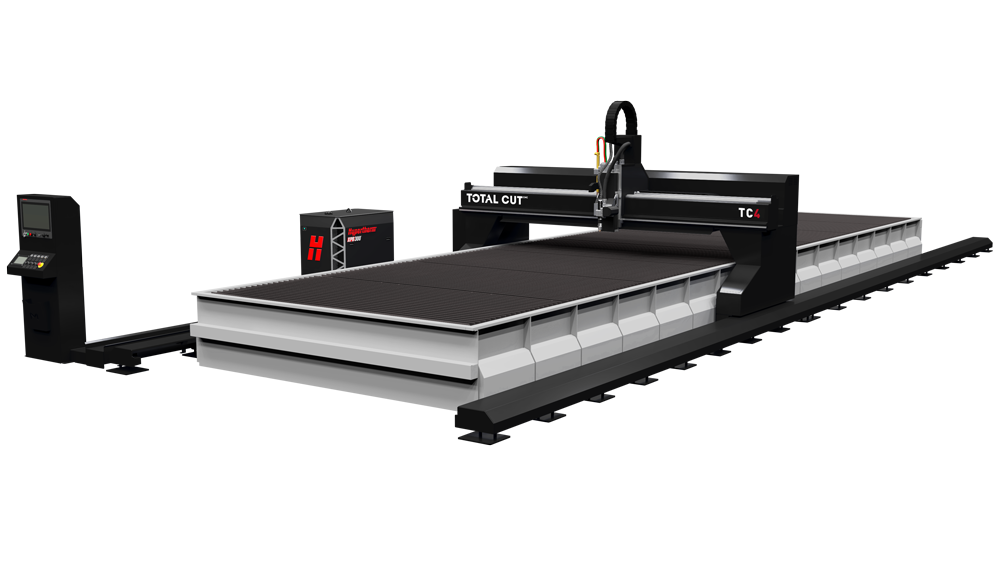

THE TC4

The Total Cut TC4™ Plasma Table is a custom industrial cutting solution for steel industries such as shipyards, plate processing facilities and structural steel fabricators.

THE TC5

The TC5™ Plasma Table is a plate processing machine engineered for the most demanding customers such as Steel Service Centers, Ship Building and Structural Steel Applications.

English

English  Français

Français