THE TC3

HEAVY PLATE CUTTING AND HIGH VOLUME

The TC3 is perfect for customers looking for accuracy and high productivity. Driven by Bosch Rexroth motors, this compact unitized machine is configured with heavy-duty components, such as high precision planetary gearboxes on all axis, offering an extremely smooth, accurate, and highly productive cutting table

OTHER CNC PLASMA TABLE MODELS

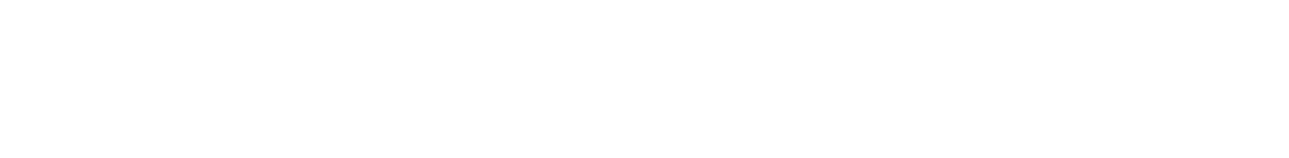

THE TC2

The Total Cut TC2™ Plasma Table is a compact industrial cutting system designed for accurate & productive high precision cutting applications.

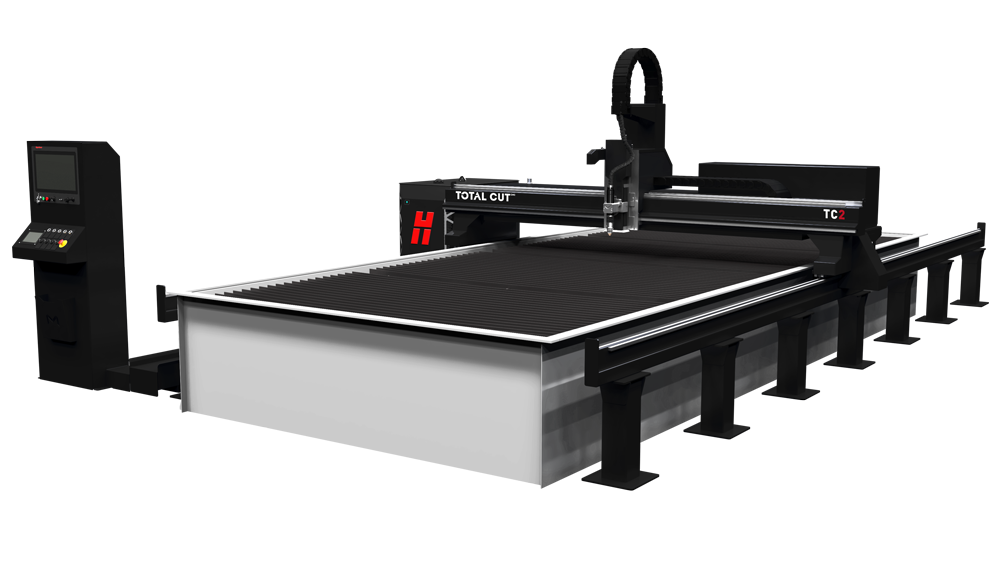

THE TC4

The Total Cut TC4™ Plasma Table is a custom industrial cutting solution for steel industries such as shipyards, plate processing facilities and structural steel fabricators.

THE TC5

The TC5™ Plasma Table is a plate processing machine engineered for the most demanding customers such as Steel Service Centers, Ship Building and Structural Steel Applications

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

English

English  Français

Français