THE TC5

HEAVY PLATE CUTTING, DRILLING AND TAPPING

The TC5 is a bridge and rails machine designed for the heavy duty drilling application. You get the best of both worlds with quality drilled holes and nice cut quality with the plasma or oxy-fuel. This table is equipped with an automatic tool changer for increased productivity.

OTHER CNC PLASMA TABLE MODELS

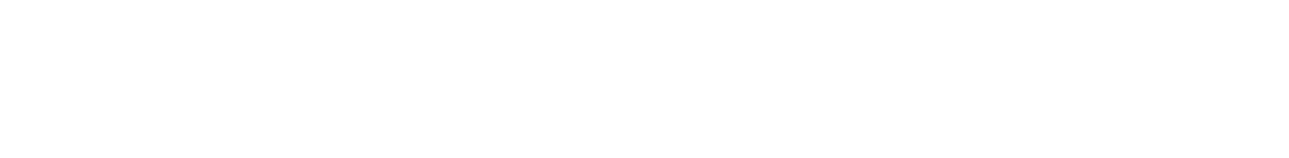

THE TC2

The Total Cut TC2™ Plasma Table is a compact industrial cutting system designed for accurate & productive high precision cutting applications.

THE TC3

The Total Cut TC3™ Plasma Table is a custom industrial cutting solution for steel industries such as shipyards, plate processing facilities and structural steel fabricators.

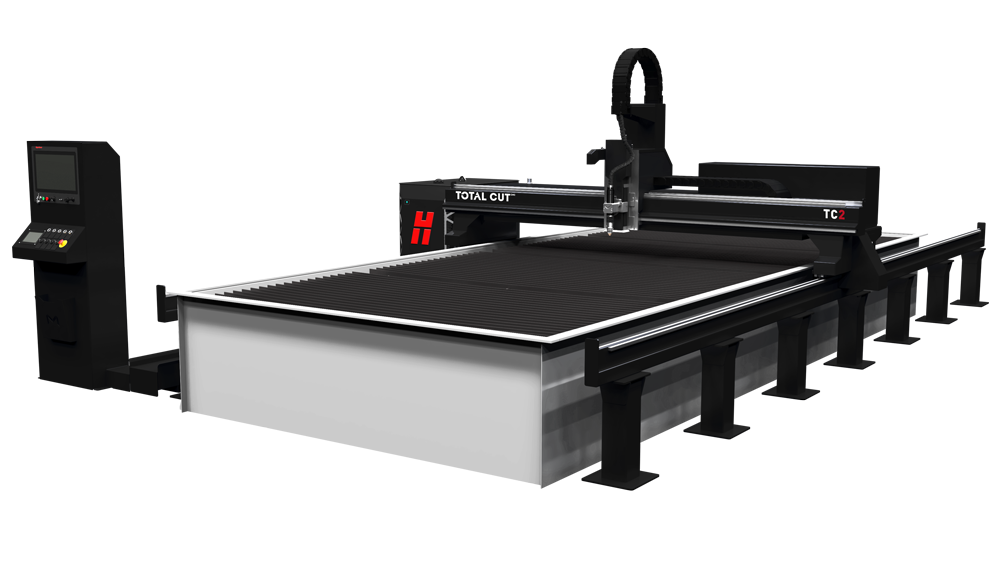

THE TC4

The Total Cut TC4™ Plasma Table is a custom industrial cutting solution for steel industries such as shipyards, plate processing facilities and structural steel fabricators.

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

English

English  Français

Français