WHY CHOOSE TOTAL CUT CNC?

We are a company that specializes in the manufacturing of industrial CNC Routers and CNC Plasma Cutting Systems with Product Specialists, Technical Support and Applications Support throughout all of North America

We offer superior quality equipment at competitive prices. Over the years, we have gained a very enviable reputation thanks to our long list of satisfied customers.

Our team, composed of passionated experts, is at your service, to follow you in the use of our machine, but also to make sure you get the right solution to help you reach higher productivity, capability and efficiency.

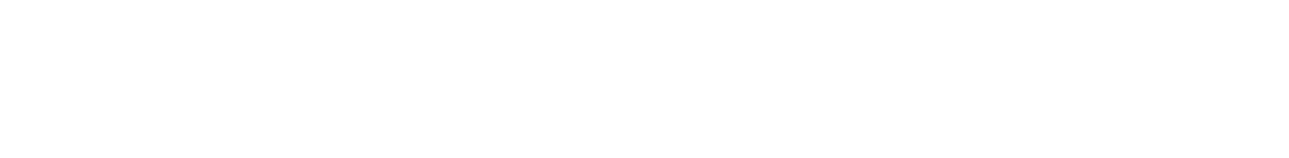

INDUSTRIAL CNC PLASMA

A wide range of dependable light industrial CNC Plasma Tables for all needs and applications.

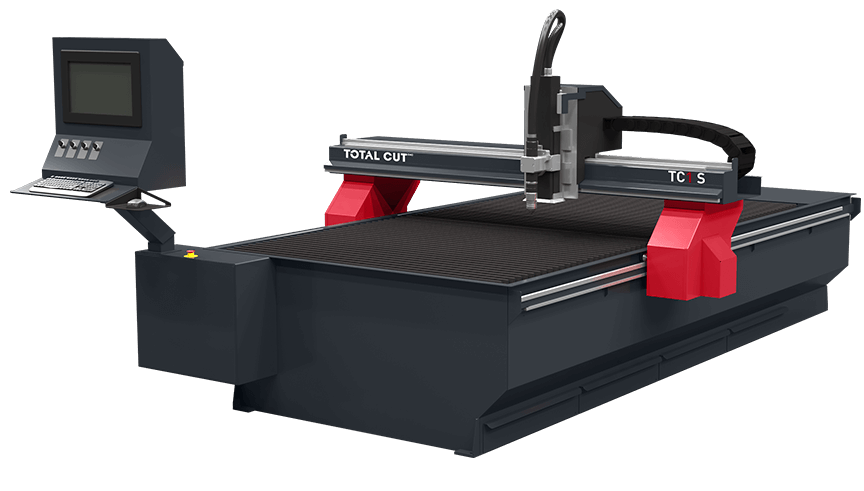

INDUSTRIAL CNC ROUTERS

Whether you need a CNC Router to process wood, plastic or any other material, Total Cut CNC has the CNC Router model you need.

REQUEST A PRICING QUOTE

Contact us to get a free personalized quote for the equipment you need

English

English  Français

Français